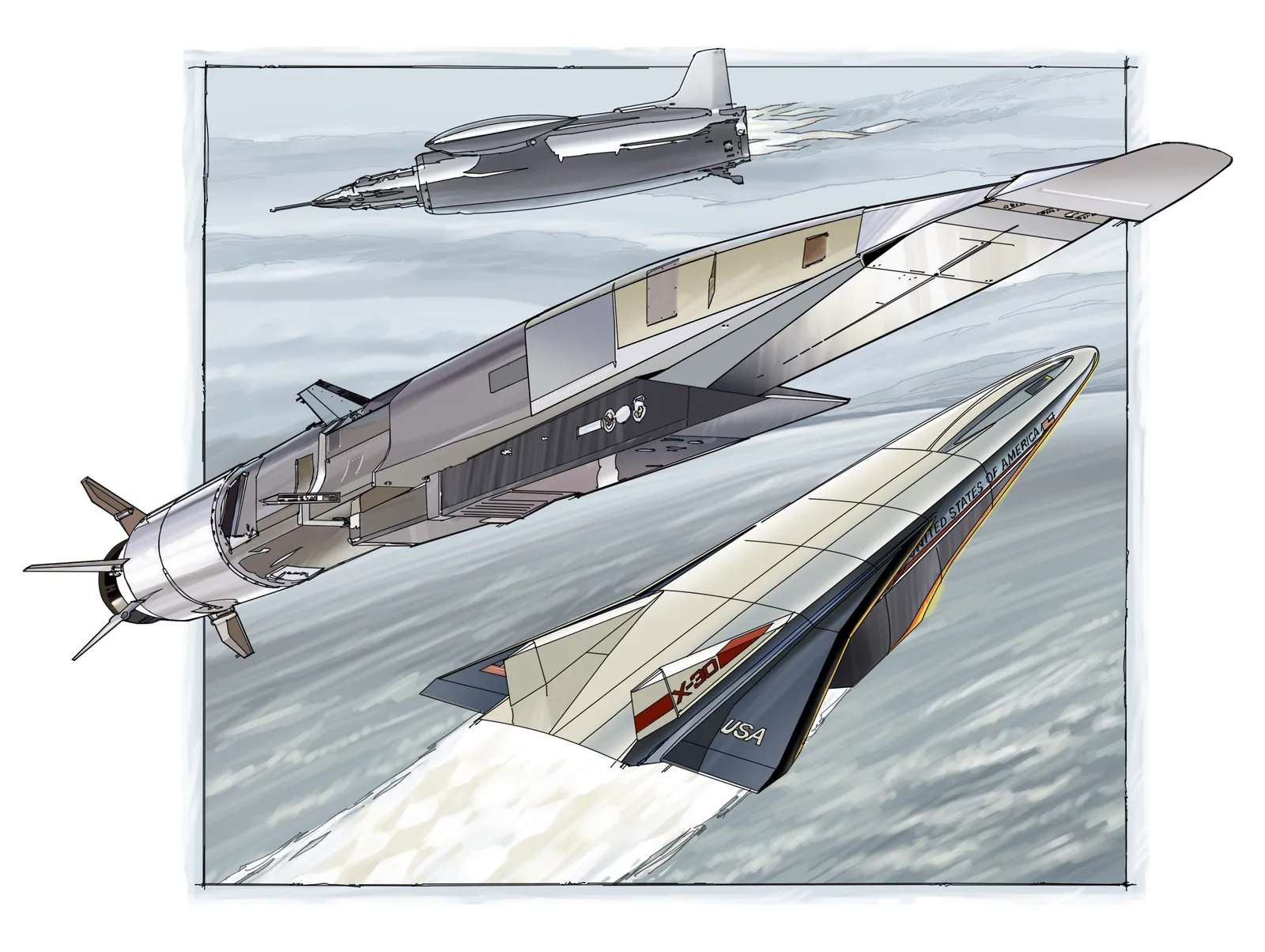

Real Scramjet Engine - As a concept, the hypersonic scramjet has been around since the 1960s, but engineers only now have the materials to realize its potential as the future of aviation.

To test its experimental X-43A — an unmanned, single-use, powered, tri-engine hypersonic aircraft — NASA pitted it against two other aircraft.

Real Scramjet Engine

The first was the Boeing B-52 Strato Fortress, which carried two vehicles under its wings to an altitude where they could "launch drop".

Sabre (rocket Engine)

Then there was the booster rocket, a modified version of a Pegasus rocket that would accelerate the X-43A after launch to a speed that its scramjet engines could power.

The second, in March 2004, was a success: the X-43A powered by a scramjet flew 24 km 11 seconds with a maximum speed of Mach 6.83 (8433 km/h).

On November 16, 2004, the third X-43A set an impressive, new airspeed record of Mach 9.6 - 11,854 km/h - at an altitude of 33,500 meters.

The flight distance from Sydney to London is only 17,000 km. The X-43A, if it can maintain performance at that distance, will make the trip in about 90 minutes. But it is a big leap into the future.

Mechanical Engineering Stuff: Scramjet (seminar Report)

"It took about 50 years to develop scramjet technology to the point where it could be demonstrated in flight," said Dr. Kevin Bockett, Boeing's senior technical fellow and chief scientist in hypersonics.

"It took a long time to analyze the physics of hypersonic flow theoretically or even simulate it in computers because of the challenge of testing the ground at hypersonic speed due to the extremely hot environment encountered at hypersonic speed and the high energy flow and temperature." It's difficult..

Scramblers require materials that can withstand the extreme heat generated at such speeds. The scramjet - from 'supersonic combustion ramjet' - operates at just around Mach 5, or five times the speed of sound (more than 5000 km/h).

"It took nearly 50 years to develop scramjet technology to the point where it could be demonstrated in flight."

After Hypersonic Missiles, Us Air Force Sets Eye On Air Breathing Hypersonic Jet

Rather than using turbofan blades to compress the air, scramjets use the forward momentum of the aircraft. It's an air-breathing creature that presents some interesting engineering challenges.

Thanks to research institutions such as the University of Queensland (UQ), the University of New South Wales (UNSW) Canberra and the Royal Melbourne Institute of Technology, Australia has been at the forefront of some areas of Scramjet design and engineering.

"Scramjet engines don't just have low moving parts, they have no moving parts," said Professor Michael Smart, mechanical engineer, director of Hypersonics and head of UG's HiShot Group.

"Until about 10 years ago, people tried to use metallic materials to build scramjets, such as titanium and nickel alloys - high-temperature alloys from the aerospace industry. But these materials just didn't have the potential."

Powerplants For Mach 5 And Beyond

Materials that can withstand extreme operating temperatures are carbon compounds, Smart said.

"Epoxy matrix is not like ordinary fiberglass. Instead it uses materials like silicon carbide as the matrix. These carbon compounds can withstand temperatures up to 1600 degrees Celsius and do not degrade. They last a long time. There are, but what? What has really changed in the last decade is our ability to manufacture them in all sorts of aerodynamic shapes.

A secondary challenge is the complexity of the flow structure in hypersonic flight, said Professor Russell Boyce, Director of UNSW Canberra Space.

“You can turn a nice, well-characterized and well-understood flow into a catastrophic flow in milliseconds, depending on the physics, and depending on what you do with the aircraft.

Is There A Real Secret Aircraft Behind Lockheed And Top Gun's Darkstar?

"With a rocket, the aerodynamics are simple - you just put a heat shield in front. It's long and thin and nothing leaks from the flow except for the fins. The engine doesn't breathe air, so nothing that flows Yes. It's just a good free combustion challenge. Scrumjets are the opposite.

Engine size, chemical combustion rate, temperature, fuel type, altitude, and therefore air pressure and oxygen mixture - all of these affect design and engineering.

"The design of ramjet and scramjet inlets and nozzles is challenging both aerodynamically, shape-wise, and structurally," Bowcutt said.

"For a ramjet or scramjet operating in the speed range greater than one Mach number, the inlet and nozzle must use variable geometry to compress the intake air and expand the engine exhaust. And they The cells they use get very hot and are made of special, high-temperature materials.

Isro's Two Stage To Orbit (tsto) Or Fully Reusable Vehicle (frv) That Takes Off Like A Normal Plane. Except, This 133 Tons Monster Utilizes Literally Everything... From Turbojet To Ramjet To Scramjet To

"The internal engine structure also requires cooling and fueling." In a scramjet, designing and manufacturing fuel injectors, which often mix fuel with air, is a challenge. It must be able to ignite the fire and keep the flame burning. It is important to maintain the pressure that releases the combustion in the engine because it can possibly lead to the engine being started.

Traditional satellite launches involve multi-stage rocket systems, which require a lot of fuel and a large amount of waste.

Rockets have traditionally been single-use vehicles, although the experiences of Elon Musk's private space company SpaceX and Boeing's XSP, a reusable first stage in development, are quickly making reusable rocket technology a reality.

Australian scientists and engineers discussed the development of a launch vehicle that uses a first-stage rocket, a second-stage scramjet and a smaller third-stage rocket. The scramjet vehicle carries the third-stage rocket to its orbit, then turns and flies back. It can be reused.

Hypersonics Act Ii

As technology advances and faster network connectivity is required, small satellites will provide constant data capacity.

The cost of sending these satellites into orbit, Smart said, is a major concern for the organizations involved.

Reusable launch vehicles will reduce this cost. But whether this solution involves Scramjet technology or something else is yet to be confirmed.

"The day Elon Musk landed his reusable Falcon rocket on the launch pad may have been the end of scramjets to access space," Boyce said.

Hypersonix To Use Siemens' Software In Design Of Its Hydrogen Fuelled Sustainable Aerospace Vehicles

"SpaceX and Blue Origin, with their style and reusable technology, are coming in at launch costs. The cost and complexity of developing scrum jets still makes it a huge undertaking.

"Scramjets would be useful for long-range, constant-speed cruises — for example, transport and jet approach — but not for long. The challenges in human evaluation of scramjet systems would be extreme."

Boyce believes this is an important time for Australia to get serious about its role in space.

"We don't have 40 to 50 years of investment in equipment. And we do it at a time when the space is changing. It's a very serious opportunity and there are a lot of young engineers who are very excited about it." "

Turbojet Ramjet Scramjet Stock Vector. Illustration Of Engine

Boeing is interested in commercializing ramjet technology to make the future of air travel faster and more efficient.

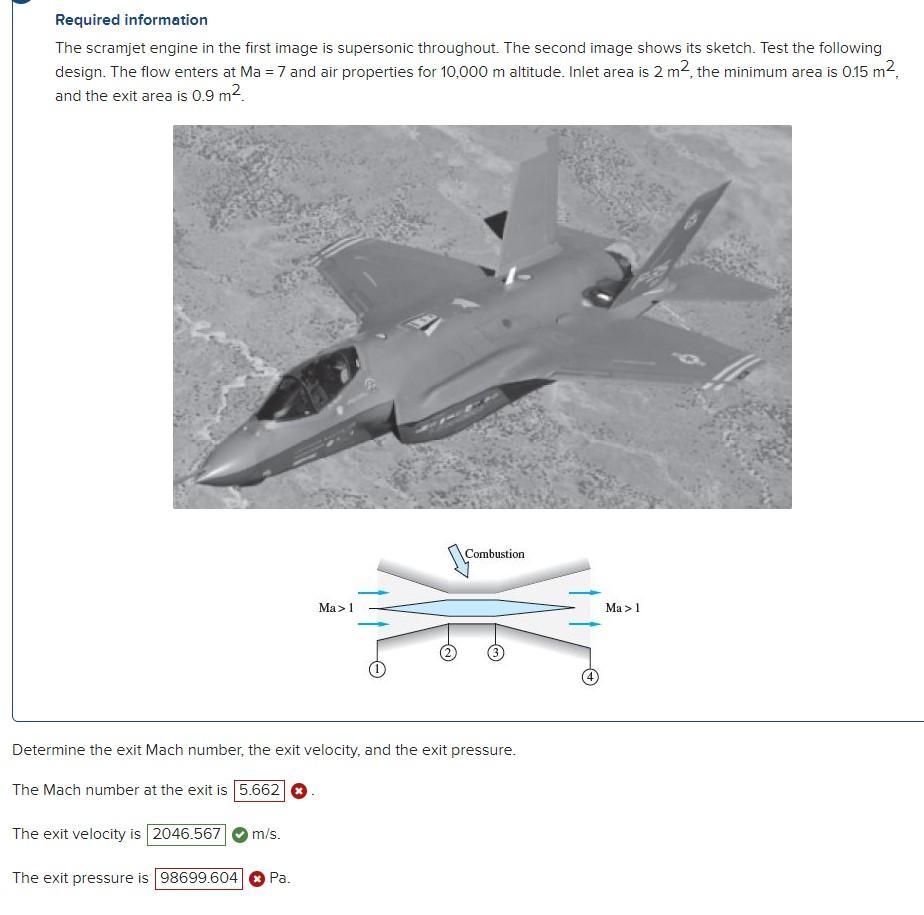

"A scramjet engine is a type of ramjet where injected fuel is burned in a supersonic stream in the engine," Bowcutt explained.

He said that ramjet and scramjet are both air-breathing jet engines that do not use compressor blades to compress the air. Ramjets last about 5 m.

"After Mach 5, the air pressure and temperature in the engine become too high to operate at optimal levels," Bowcutt said.

Optimization Of Ramjet Engine Design And Combustion

"To prevent this condition, the air in the engine is allowed to remain at supersonic speed, which by definition makes it a scramjet.

"So, the type of speed engine used for air-breathing flight: the turbofan/turbojet at about Mach 3, the ramjet at about 5, and the scramjet beyond."

It is a hybrid of this technology that interests Boeing. Bowcutt said the aerospace giant has created an initial passenger plane concept — the Mach 5 — that could have commercial or military applications.

"It works with what's called a turbo-ramjet engine, which is the integration of a turbofan and a ramjet engine into a combined propulsion system," he explained.

Aussie Hydrogen Powered Hypersonic Spaceplane To Become A Real Game Changer

"It is too early to estimate when hypersonic flight for world travel will be a reality. Some of our studies show that conceptually it could be possible as early as 10 to 20 years. However, its limits More likely to run for . 20 to 30 years."

Previous Post University Gets Funding To Innovate In Automotive Technology Previous Post Using Smart Sensors To Improve Measurement And Data Reliability

Chris Sheedy is a professional writer whose work has taken him to the UK, USA, Europe and China. He has a passion for big things – ideas, organizations, infrastructure, achievements, brands – and the people and processes needed to make them a reality.

Scramjet rocket engine, scramjet engine ppt, ramjet vs scramjet engine, scramjet engine, scramjet engine diagram, indian scramjet engine, air breathing scramjet engine, hypersonic scramjet engine, scramjet engine design, scramjet engine test, what is scramjet engine, scramjet engine pdf

0 Comments